We Make it Easy

Truly Unique Custom Merchandise

Join millions of creatives, entrepreneurs, and marketing departments that rely on The/Studio to create inspiring custom products to help build their brand.

We Make it Easy

Join millions of creatives, entrepreneurs, and marketing departments that rely on The/Studio to create inspiring custom products to help build their brand.

Make stuff you’d actually buy. Create beautiful, retail-ready products with the same quality control standards as leading fashion brands.

Let your imagination run wild. We create every product from scratch, so you can customize every last detail.

No more sticker shock. Get small-batch custom manufacturing with low upfront costs for eye-widening profit margins.

No timeline is too tight for our rapid small-batch supply chain – let us know when you’ll need your products, and we’ll make it happen!

Design premium enamel pins, die-struck pins, lapel pins, and more to add a pop of personality to an outfit or celebrate an achievement.

Customize metal, PVC, and embroidered keychains to help your customers keep track of their valuables in style.

Think outside the tee. Design 100% custom hats, beanies, and socks to make a unique statement.

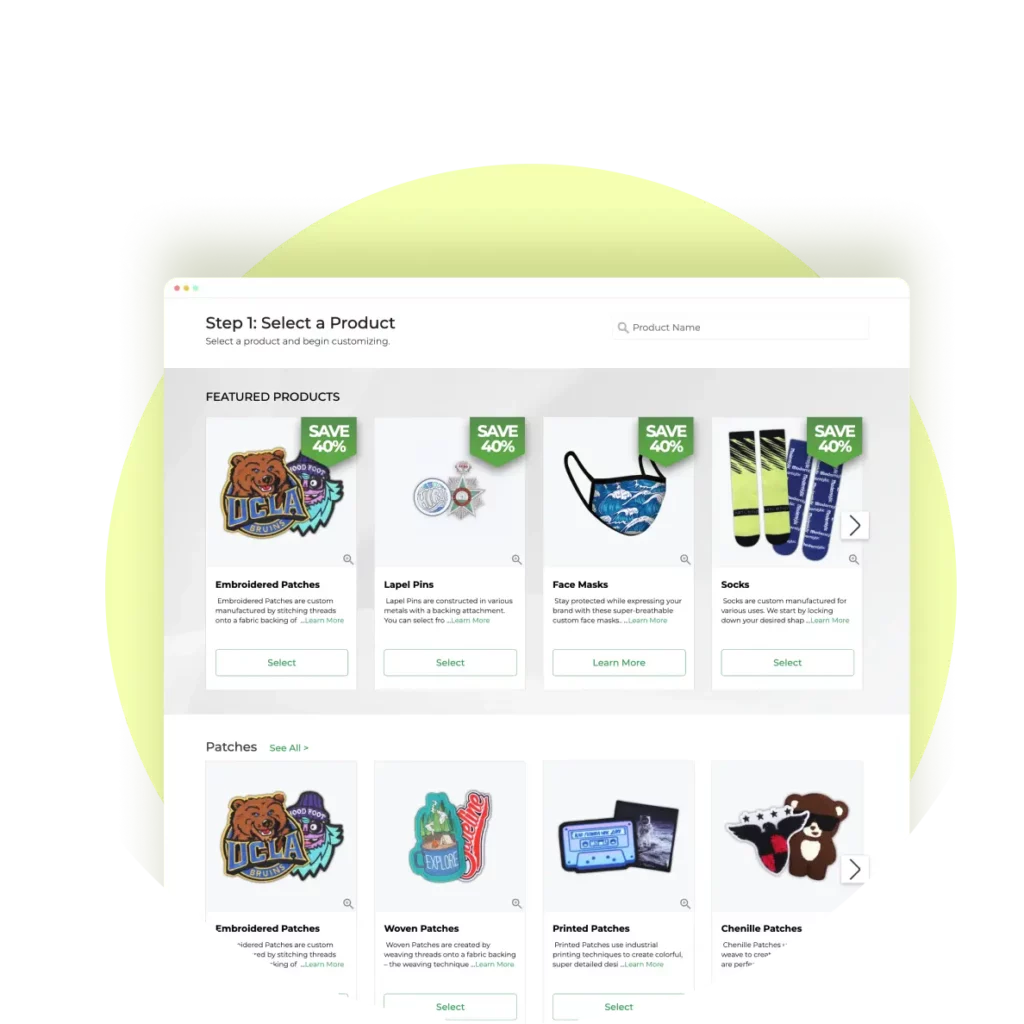

Go from a cool idea to an even cooler product – in just five easy steps.

Select the product you’d like to bring to life with our online custom product creation tool – or talk to one of our Customer Success Representatives on the phone to kickstart your project.

Make it zany, retro, sleek, sophisticated, fluffy, colorful, or anything in-between with unlimited customization possibilities.

Upload your own artwork if you have it, or work with one of our pro in-house designers free of charge.

We’ll send over a mockup or physical sample for your approval, then make as many tweaks as it takes until you’re 100% satisfied – seriously, as many as you want!

We’ll send your order to your doorstep with free tracked shipping. Then, all that’s left to do is distribute your gorgeous custom products! (Or keep them all to yourself).

It’s easy (and fun!) to create custom products with our on-demand manufacturing platform. See for yourself!

The Studio Technologies, Inc.

1055 E. Colorado Blvd., Suite 500,

Pasadena, CA 91106

Talk with a real human:

Accessories