Best places to manufacture your products in 2025

Once you come up with a groundbreaking product idea and validate the prototype, you face a new challenge: finding the best places to manufacture your products.

We’re talking not only about geographical location, but also about understanding the main pros and cons of domestic and overseas production. Choosing where to manufacture your products is the most critical decision for any brand or entrepreneur. It significantly impacts the product quality, production costs, supply chain efficiency and even legal compliance.

Key takeaways:

Choosing where to manufacture affects cost, quality and delivery.

Domestic manufacturing offers faster turnaround and easier communication, while overseas production lowers costs and increases scale.

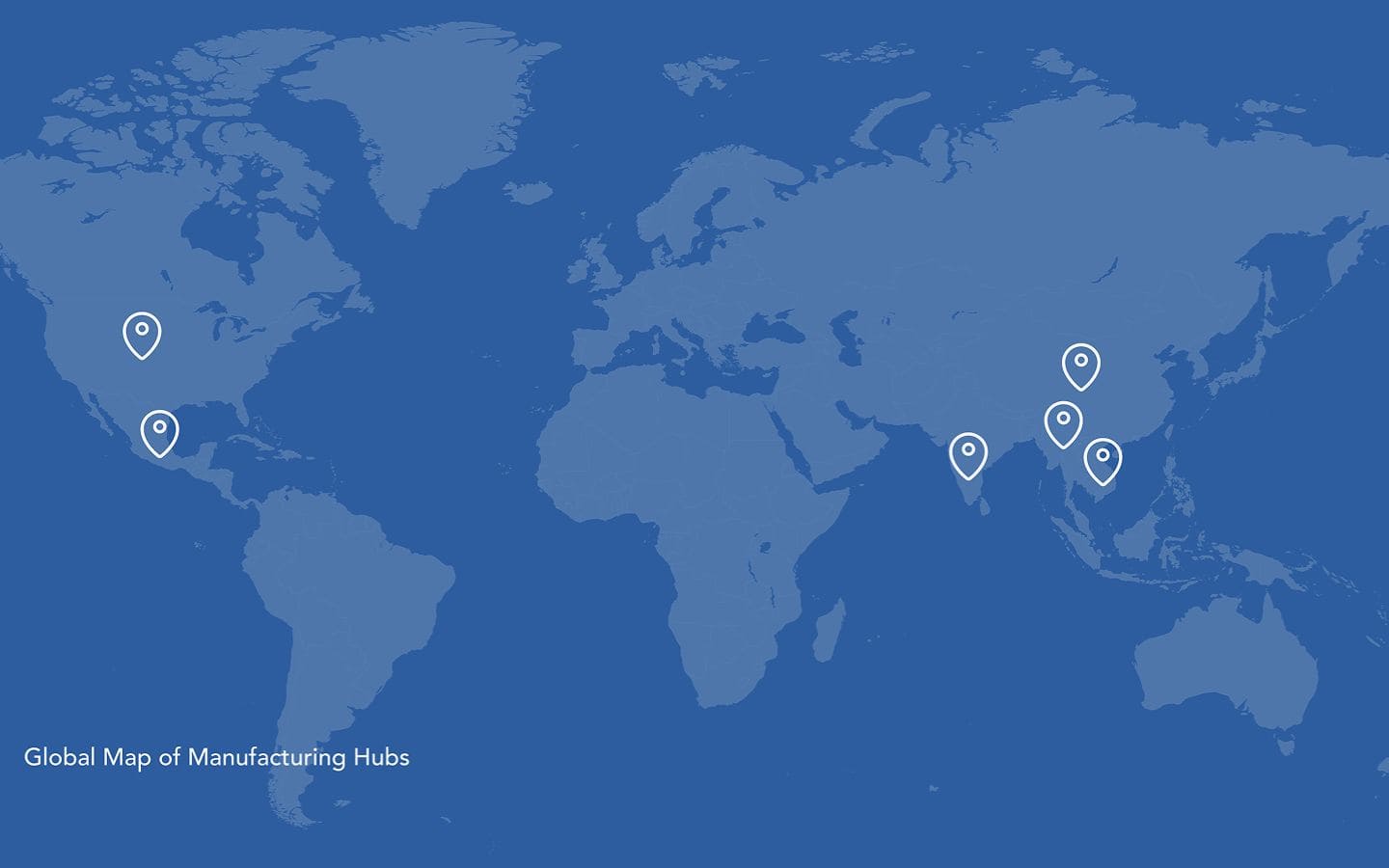

Top manufacturing countries in 2025 include China, Vietnam, India, Thailand and Mexico, each with unique strengths.

What is a manufacturer?

A manufacturer is a company or facility that produces goods at scale. They transform raw materials into finished products, using specialized equipment, processes, and expertise.

Some manufacturers handle the full process, from sourcing materials to packaging, while others specialize in a single step of production.

Working with the right manufacturer ensures your vision becomes a high-quality product delivered on time.

Choosing between domestic vs. overseas manufacturing

When choosing where to produce your items, the first major decision is between domestic (within your own country) and overseas manufacturing (outside of your country).

Domestic manufacturing

Pros:

Faster turnaround times: Shorter shipping and quicker fulfillment for local markets.

Easier communication: Using the same language, culture, and time zone makes collaboration smoother.

Stronger IP protection: Tighter legal frameworks reduce the risk of intellectual property theft.

Cons:

Higher costs: Labor, materials, and operating expenses are generally more expensive.

Limited capacity: Fewer factories and less specialization compared to overseas hubs.

Less scalability: Can be harder to ramp up quickly for very large orders.

Overseas manufacturing

Pros:

Lower production costs: Access to affordable labor and materials reduces unit price.

Specialized expertise: Overseas hubs, such as China, offer advanced capabilities across multiple industries.

High scalability: Easier to produce large volumes for global demand.

Cons:

Longer lead times: Extended shipping and customs clearance can slow delivery.

Quality and compliance risks: Factories may not always follow the same standards as domestic ones.

Complex logistics: Import duties, freight, and international regulations add layers of complexity.

Many brands work with overseas manufacturing in Asia, especially China, due to the balance of cost, speed, and quality.

Key factors when choosing the best place to manufacture

1. Production cost vs. quality

Lower cost doesn’t always mean better value. Cutting corners can damage your brand reputation. The most successful businesses strike the right balance between cost efficiency and quality craftsmanship.

China remains the global leader because it delivers both competitive pricing and advanced capabilities in textiles, electronics, plastics, and more.

Other regions like Vietnam, India, Thailand, and Mexico are also growing in demand for brands that balance price with specialization.

💡 Read more about why Thailand is a great opportunity for brands looking to source high-quality apparel.

2. Expertise

Some regions are known for specific product expertise. China for mass production and electronics, Vietnam for textiles, Italy for luxury fashion, and the U.S. for advanced manufacturing.

Choosing the best place to manufacture your product depends on aligning your industry with local expertise.

3. Logistics and shipping

Location impacts lead times, freight costs, and even customs regulations.

For businesses targeting U.S. customers, Mexico offers nearshoring advantages, while Eastern Europe provides similar benefits for EU markets.

💡 Read more on the importance of a diversified supply chain.

4. Scalability and flexibility

If you anticipate scaling quickly, choosing a manufacturing hub with large capacity and reliable infrastructure is essential.

Countries with established supply chains and industrial parks (like China and India) may serve you better than emerging markets with limited capacity.

5. Sustainability, compliance & quality control

Modern consumers and retailers care about ethical sourcing. Manufacturing in regions with strong labor standards and environmental policies can boost your brand image and help you avoid compliance issues.

No matter where you manufacture, compliance and quality are essential. Overseas factories may not always follow the same regulations as domestic suppliers, so you need to confirm standards like:

Product safety certifications.

Worker welfare practices.

Environmental impact regulations.

Quality assurance systems.

At THE/STUDIO, we vet every partner factory to ensure compliance, providing brands with peace of mind and reliable production.

How to find a manufacturer

Define your product needs: Material, dimensions, customization, and budget.

Research potential regions: Weigh domestic vs. overseas advantages.

Identify trusted manufacturers: platforms like THE/STUDIO help connect you with vetted factories.

Request samples: Always test quality before committing.

Negotiate terms: Clarify pricing, timelines, and order minimums.

Inspect and monitor: Ensure quality control throughout production.

Frequently asked questions

What are the types of manufacturing processes?

There are five main types of manufacturing processes:

Repetitive manufacturing: Producing the same product at scale using assembly lines, ideal for high-volume goods like consumer electronics or cars.

Discrete manufacturing: Similar to repetitive, but allows customization and frequent changeovers, often used in aerospace and tech.

Job shop manufacturing: Small-batch, highly customized production handled at specialized workstations, common in footwear, printing, and defense.

Continuous manufacturing: Non-stop production using raw materials like liquids, gases, or powders, typically in pharmaceuticals, energy, or chemicals.

Batch manufacturing: Producing items in specific batches as needed, widely used in food, beverage, and pharmaceutical industries to reduce waste.

Understanding these processes helps you decide which is best suited to your product and growth goals.

Where is the best place to manufacture products?

China is currently the best place for cost-effective, high-quality, and scalable manufacturing. However, alternatives like Vietnam, India, Thailand, and Mexico are becoming strong options.

How do you find a manufacturer to make your product?

Finding a manufacturer begins with clearly defining your product idea and its requirements, such as materials, dimensions, budget, and order volumes. You can:

Search online directories.

Attend trade shows to meet suppliers in person.

Work with sourcing platforms that connect you directly with vetted, reliable factories.

Always request samples, compare pricing, and check references before committing.

How can I create my own product?

Creating a product involves a full product development process to turn an idea into a tangible item ready for sale:

Idea generation: Identify a problem or market need.

Research and validation: Test whether customers want your solution.

Prototyping: Work with designers and manufacturers to create a sample.

Testing and iteration: Refine based on feedback.

Sourcing and production: Partner with a manufacturer to bring it to market.

💡 Read more about how to validate your product idea.

Which country is number 1 in manufacturing?

China is the world’s top manufacturing hub, producing more goods than any other country, earning the title of “the world’s factory”.

It became highly attractive to manufacturers thanks to its advanced infrastructure, technology, skilled labor force, and well-established global supply chain network.

The U.S., Japan, and Germany follow behind, but China continues to dominate global output.

How to connect with Chinese manufacturers?

There are several ways to connect with manufacturers in China:

Attend trade shows like the Canton Fair, which is one of the largest sourcing events in the world.

Explore B2B marketplaces such as Alibaba, where thousands of factories list their products.

Work with sourcing partners like THE/STUDIO, which pre-vets and manages reliable Chinese factories so you don’t have to worry about quality or communication barriers.

How do I get my product made in China?

Define your specifications, request samples, and work with a trusted factory. THE/STUDIO simplifies this process by managing sourcing and quality control for you.

In addition, it’s important to understand timelines, shipping methods, and local regulations before committing to production.

Building a clear agreement with your factory (covering costs, delivery schedules, and quality standards) helps avoid delays and ensures your product arrives exactly as intended.

How to get wholesale products from China?

You can purchase through wholesale marketplaces, sourcing agents, or directly via manufacturers. THE/STUDIO offers wholesale options with customizations.

To buy wholesale from China, have the following steps in mind:

Identify your product and market demand.

Research suppliers.

Request samples before placing large orders.

Negotiate pricing and terms carefully.

Confirm compliance with certifications and import laws in your country.

Do I need a business license to wholesale from China?

While Chinese suppliers need an export license to legally ship goods abroad, importers (you) generally need a business license in your own country to buy wholesale from China and comply with import and tax regulations.

This ensures you can clear customs, pay duties, and legally resell products.

For small test orders or samples, a license is not always required, but once you scale into bulk imports, customs authorities typically ask for business credentials. Without them, shipments may be delayed, rejected, or fined.

How to find the right manufacturer in China?

Research factory capabilities, verify compliance, and check reviews. To determine if a manufacturer is reputable, look for certifications, customer references, and third-party audits.

THE/STUDIO pre-vets every partner factory to ensure reliability and eliminates guesswork by guaranteeing manufacturer credibility.

Final thoughts

Choosing the right place to manufacture your product is one of the most important decisions you’ll make as a business owner. Domestic production offers control and speed, while overseas options, especially China, deliver affordability and scalability.

The best choice depends on your product, budget, and long-term goals. What matters most is working with trusted manufacturers who ensure quality, compliance, and on-time delivery.

At THE/STUDIO, we’ve built a network of vetted factories worldwide to make this process easier, safer, and more transparent. Whether you’re launching your first product or scaling an established brand, we help you bring your vision to life.