How a Custom Patch is Made: From Thread to Finish

Some companies, like Tommy Breeze, have even built their entire brand identity around the distinct charm of custom patches, making them a cornerstone of their aesthetic. High-fashion powerhouses such as Gucci and Louis Vuitton have likewise embraced the patch, integrating intricate embroidered and woven designs into their premium collections to add bespoke flair and reinforce their iconic status

Think beyond traditional uses; from exclusive fashion drops and coveted club memberships to bespoke merch kits and community swag, a custom patch is a tangible piece of your brand's essence.

But what goes into making such an impactful piece?

Join us on an inspiring, behind-the-scenes journey, where we'll reveal not just how a patch is made, but the incredible possibilities it unlocks for your brand. Whether you're dreaming up your first design or envisioning your next iconic collection, this guide is your invitation to craft something truly memorable and beautiful.

Step 1: Your Vision, Unveiled | From Idea to Artwork

Every extraordinary patch begins with a spark, a moment of inspiration, a rough sketch, or a bold logo. The exciting truth? You absolutely don't need to be a seasoned designer to get started. Many of the most successful custom patch projects begin with nothing more than a simple drawing, a low-resolution image, or even a hand-scribbled idea. It's in this raw creativity that the most beautiful concepts often emerge. That’s why at THE/STUDIO, we offer free design support, transforming your early concepts into professional, production-ready masterpieces.

This initial stage is a collaborative journey where your vision truly takes shape, guided by our expertise. We're proud to say that custom patches were the very first product we ever manufactured, making us true experts in custom manufacturing. Our team of dedicated Creative Specialists embodies this deep knowledge. Many of them have been with us since the beginning, bringing years of unparalleled experience and a profound understanding of what makes a patch truly "pop."

In addition, our Creative Specialists are specifically trained in the nuances of patch design and production, allowing them to provide expert guidance. They know precisely when to recommend 100% embroidery to make your design stand out with rich texture, or when 50% embroidery might be better to ensure your text details are crystal clear and impactful. They understand the intricacies of different borders and the subtle differences that elevate a good patch to a great one.

Simply tell us what you want your patch to accomplish, and our Creative Specialists will leverage their in-depth knowledge to figure out the best approach.

We refine your idea: Turning your raw concept into a polished design.

We guide your choice: Recommending the perfect patch type (embroidered, woven, PVC, etc.) that best expresses your aesthetic.

We perfect the details: Aligning on precise sizing, an inspiring color palette, and the ideal level of intricate detail.

We ensure your satisfaction: Sharing digital proofs for your review, feedback, and any necessary revisions until it’s perfect.

💎 Design Tips: This is your moment to deeply infuse your patch with your brand's core values, unique aesthetic, or the narrative of your product line. A well-designed patch isn't just an accessory; it's a powerful visual statement and a captivating storytelling tool.

Step 2: The Canvas & Threads | Material Selection & Preparation

Once your vision is perfected, we meticulously prepare the raw materials that will bring it to life. Most patches are crafted from durable twill fabric, vibrant polyester threads, or custom-molded PVC; each offering a distinct feel and aesthetic. Our team will also help you determine the right custom patch type for your specific project. For example, if you're aiming for something nostalgic with a simple design, Chenille is a fantastic option. If you prefer a classic, timeless look, embroidered patches are ideal. And for the most luxurious and distinguished appearance, Bullion patches are unmatched.

We also carefully select the backing material, considering how your beautiful patch will ultimately be experienced, whether it's sewn seamlessly onto a garment, ironed on with ease, attached with versatile Velcro, or simply peeled and adhered.

🌱 Sustainability Note:

More and more eCommerce brands are choosing eco-conscious materials, like recycled polyester threads, organic cotton, and biodegradable backings, for their custom patches. This shift isn’t just ethical; it’s strategic: 70% of consumers say they are more likely to buy from brands that clearly label sustainable packaging, and 69% expect brands to offer sustainable packaging by 2025

Step 3: Breathing Life into Pixels | Digitizing the Design

This crucial step is where your visual design transcends into a language machines understand. For embroidered and woven patches, digitizing converts your artwork into precise instructions for our machinery, dictating every stitch, every layer, and even the ideal thread density. For PVC patches, this stage involves creating a precise mold that will give your patch its unique three-dimensional form.

This step requires technical artistry, especially for complex designs with gradients, tiny text, or color blending. For embroidered patches, digitizing determines how your patch feels in the hand, and how long it lasts.

🎯 Growth Insight:

Brands that optimize for quality detail in their patches see up to 35% higher repurchase rates, especially when used as part of a product or unboxing experience. Quality is memorable.

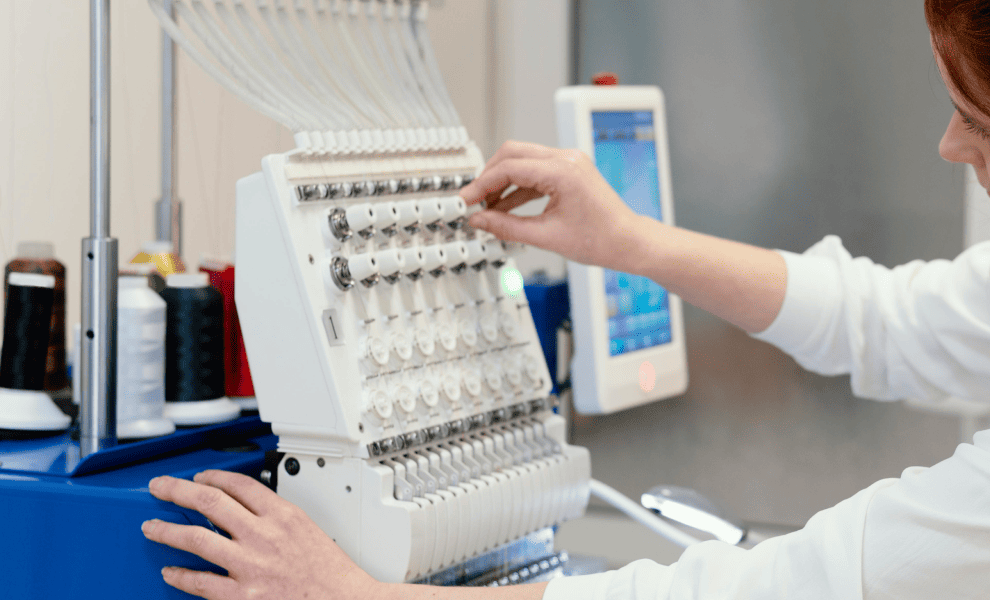

Step 4: The Art of Production | Stitching Your Masterpiece

This is where your design truly comes to life! Depending on your chosen patch type, industrial-grade machinery meticulously brings your vision into tangible form.

For embroidered and chenille patches, your design file is fed into high-precision machines capable of executing tens of thousands of stitches – sometimes over 15,000 per patch, depending on its size and intricate detail. Witnessing this process is like watching a painter bring a canvas to life, stitch by precise stitch. Woven patches are crafted on specialized looms that interlace threads to create fine, detailed designs. And for PVC patches, your custom mold comes into play, as liquid PVC is injected and cured to form durable, vibrant, three-dimensional designs.

Each beautiful patch undergoes a meticulous process:

Precise Thread Loading: Ensuring every color is perfectly placed.

Expert Stitching: Or weaving/molding for PVC, bringing your design to tangible form.

Flawless Edge Finishing: With elegant merrowed or clean heat-cut borders.

Fun fact: Our machines can produce over 50,000 patches per day, yet every order still receives manual quality checks.

Step 5: The Perfect Finish | Cutting, Backing & Beyond

Once stitched to perfection, your patches are precisely cut into their final shapes. Your options are limitless:

Die-cut: For truly custom, unique silhouettes.

Classic Shapes: Pristine circles, squares, or rectangles.

Laser-cut edges: For unparalleled precision and clean lines.

Then comes the thoughtful selection of backing: durable iron-on glue, secure Velcro, versatile adhesive, or simply a classic plain back. This choice defines how your customers will interact with your beautiful creation, whether it's proudly sewn onto a beloved bag, boldly applied to a favorite jacket, or discovered as an exclusive surprise in a limited-edition PR kit.

Step 6: Delivering Your Creative Vision – Packaging & Dispatch

Whether you’re ordering 50 or 50,000, every patch gets the same careful finish. After final inspection, we pack and ship your patches, usually within 10–12 business days from final approval.

How Custom Patches Elevate Fast-Growing Brands:

Elevate Your Products: Adding a bespoke, tangible touch to clothing, hats, bags, or even an unexpected flair to your product packaging.

Spark Organic Engagement: Inspiring customers to share their creative uses on social media.

Forge Deeper Loyalty: Cultivating a strong brand identity and sense of community.

Real Brands. Real Inspiration. Real Impact.

Let’s look at a few real-world examples:

Heritage Threads Co. added woven patches to their subscription box and saw a 22% jump in Instagram mentions.

Kickstarter brand Overlooked used limited-run patches for backers and doubled their funding goal in 48 hours.

Streetwear label PRXJECT included embroidered patches in all orders and created a viral campaign around #PatchDrop.

One of the most remarkable aspects of custom patches is their cost-effectiveness. Depending on the quantity and specific options, patches typically range from as low as $0.20 to about $4 per piece (at the very high end), with an average cost of around $1. This incredible affordability unlocks a world of possibilities: you can give them away as delightful surprises, use them as premium trim on clothing, caps, and bags, or even sell them as standalone items with super high margins, sometimes over 95%. When integrated into apparel, patches don't just enhance the product; they significantly enrich the storytelling of your brand, creating a deeper connection with your audience.

Final Thoughts: Your Opportunity to Create Something Beautiful

Creating a custom patch is so much more than a manufacturing process; it's a profound opportunity to infuse your brand with tangible identity and artistic expression. It’s a chance to connect emotionally with your customers, leaving a lasting impression that adorns their clothes, personalizes their belongings, and resonates in their hearts.

And the most liberating part? You don’t need to have every detail figured out on your own. That’s precisely what we're here for, to be your creative partner every step of the way.